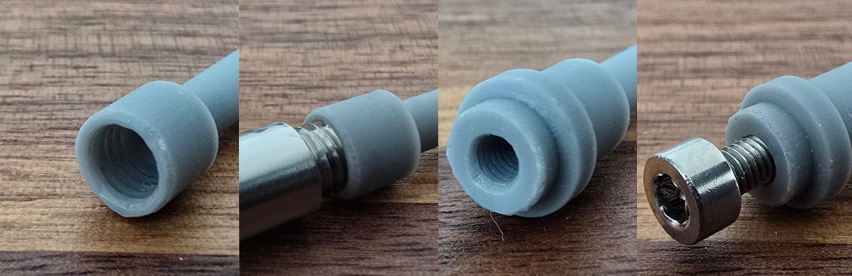

Integrating threaded features directly into 3D printed parts often results in poor durability and performance. A more reliable alternative is the use of metal inserts, which can be embedded during or added after printing.

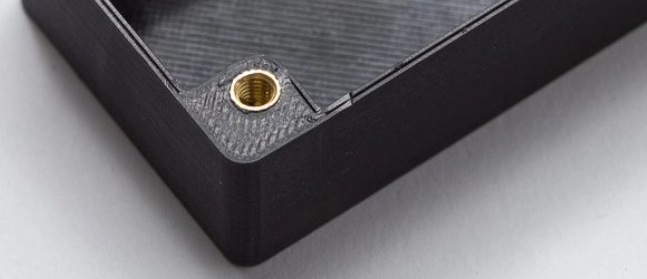

However, these inserts occupy additional space and typically require a surrounding structure or dome of printed material to ensure secure placement.

But, sometimes certain design constraints leave no usable space whatsoever…

Despite operating with minimal wall thickness, we successfully incorporated functional M5 and even M3(!) threads directly during the printing process.

Struggling with tiny features during product development? We’re here to help.!

No responses yet