Achieving the right surface finish on molded parts is crucial for both aesthetics and functionality. The finish influences part appearance, texture, release properties, and even durability. Two widely used standards—SPI (Society of Plastics Industry) and VDI (Verein Deutscher Ingenieure)—define surface textures for molds.

In this post we highlight the SPI standard. This standard categorizes finishes primarily based on polishing methods. These categories ensure consistency in molded parts, especially in industries requiring high cosmetic quality.

| SPI A Standard | Surface Roughness | Method | Finishing Look |

|---|---|---|---|

| SPI A1 | 0.012 to 0.025 µm | 6000 Grit Diamond | Super High Glossy |

| SPI A2 | 0.012 to 0.025 µm | 3000 Grit Diamond | High Glossy |

| SPI A3 | 0.05 to 0.10 µm | 1200 Grit Diamond | Normal Glossy |

| SPI B Standard | Surface Roughness | Method | Finishing Look |

|---|---|---|---|

| SPI B1 | 0.05 to 0.10 µm | 600 Grit Paper | Fine Semi-glossy |

| SPI B2 | 0.10 to 0.15 µm | 400 Grit Paper | Medium Semi-glossy |

| SPI B3 | 0.28 to 0.32 µm | 320 Grit Paper | Normal Semi-glossy |

| SPI C Standard | Surface Roughness | Method | Finishing Look |

|---|---|---|---|

| SPI C1 | 0.35 to 0.40 µm | 600 Grit Stone | Fine Matte |

| SPI C2 | 0.45 to 0.55 µm | 400 Grit Stone | Medium Matte |

| SPI C3 | 0.63 to 0.70 µm | 320 Grit Stone | Normal Matte |

| SPI D Standard | Surface Roughness | Method | Finishing Look |

|---|---|---|---|

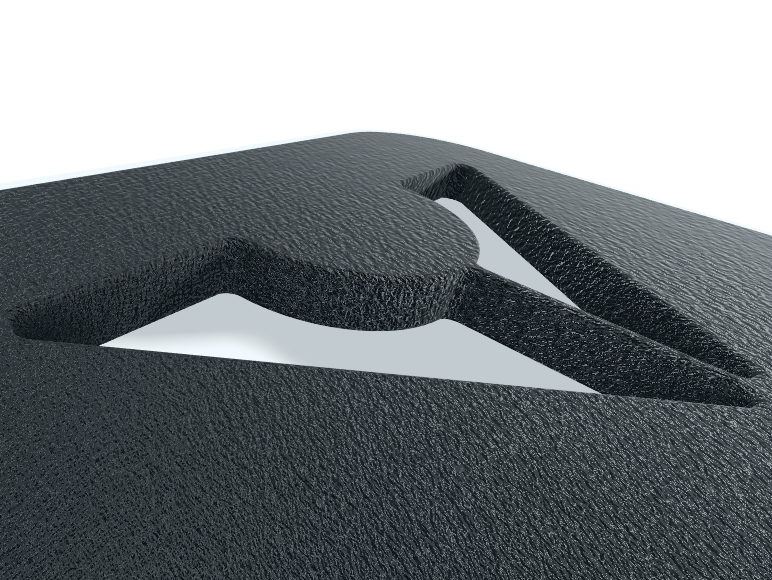

| SPI D1 | 0.80 to 1.00 µm | Dry Blast Glass Bead | Satin Textured |

| SPI D2 | 1.00 to 2.80 µm | Dry Blast | Dull Textured |

| SPI D3 | 3.20 to 18.0 µm | Dry Blast | Rough Textured |

Every surface finish comes with its own advantages and constraints when it comes to compatibility with both the part material and mold material. We’ll explore that in more detail later on..

Selecting the right finish depends on the part’s function—whether it’s a sleek consumer product, an industrial component, or a high-grip surface. A well-chosen surface finish enhances durability, reduces defects, and optimizes molding efficiency.

Need help picking the right finish for your project? Let’s talk!

No responses yet